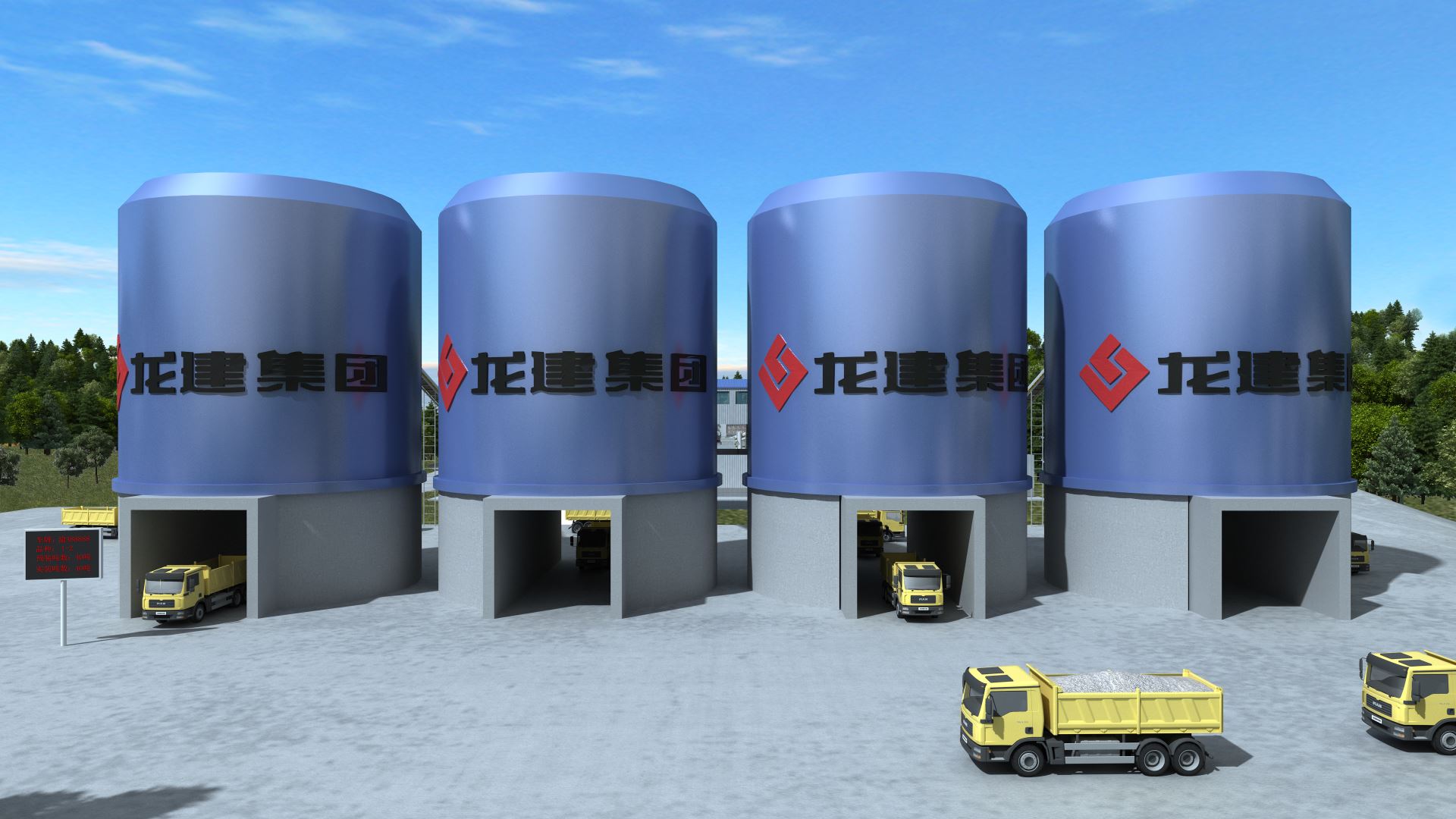

As we all know, granite is a raw material with relatively high hardness, and the general heavy hammer crusher is good at processing soft and hard materials. However, Longjian Group's PCZ heavy crusher series products can achieve large crushing ratio and high productivity crushing equipment. At the same time, the output is as high as 3000t / h. Many users doubt whether the hammer crushing can process granite and other materials. However, Longjian Group's heavy hammer breaking is completely capable of breaking granite, but the wearable parts broken by the heavy hammer will have certain wear.

.jpg)

The use of Longjian Group's heavy hammer to break the granite production line, the initial cost of the user's input is relatively low, and the production line is easy to operate. However, considering the high hardness of granite, the stone material will quickly wear out the consumable parts of the hammer crusher, so the cost will be higher in later maintenance. Therefore, Longjian Group also recommends the operation of two machines. The primary crusher adopts jaw crusher, and the secondary crusher uses cone crusher. Both of these equipments are also high-pressure-resistant equipment. High, and the production cost will be relatively low, but the initial cost of equipment is relatively high. Therefore, users can choose granite crushing production line equipment according to their own needs.

At the same time, in the crushing production line, there are often cases where the hammer breaks the bearing and locks up. Due to the large amount of heat generated during the operation of the bearing, the heat cannot be dissipated in a short time, resulting in a sharp increase in the bearing temperature and eventually bearing lock.

For this reason, the senior editor of Longjian Group shares with you the main reasons that cause the bearing to heat up:

1. Improper assembly

1. The outer ring of the bearing and the bore of the bearing seat or the inner ring of the bearing and the shaft are improperly fitted during assembly.

During the assembly process, there was no grinding of the inner hole and the measurement of its size, and the new bearing was replaced for assembly. After the test, the temperature rise was found to be too high. When disassembling the measurement, it was found that the bearing housing hole has been deformed, which squeezed the outer ring portion of the bearing, resulting in a smaller radial clearance of the bearing, uneven rolling of its rolling elements, and increased wear. The gap between the inner ring of the bearing and the shaft is too large, and the inner ring of the bearing rotates with the rolling body and the shaft, and the friction causes the bearing to heat and vibrate.

2. Improper control of bearing heating temperature during assembly.

When the temperature of the bearing heater is adjusted too high during the heating operation, it will cause tempering and reduce the hardness and accuracy, thereby increasing the bearing temperature and causing the bearing to wear and damage.

3. Improper adjustment of bearing clearance during assembly.

In actual work, many installations are sometimes debugged only by feel, and the gap is too large or too small to meet production needs. If the axial gap is too small, it will easily cause bearing heating, accelerate pitting corrosion, and even cause the rolling elements to be stuck or glued to damage; if the axial gap is too large, the impact force of the motion pair will increase and the rigidity will decrease, which will result in operation. The abnormal sound may even cause severe vibration or damage the cage.

2. Second, the oil seal problem

The oil seal is a sealing element for sealing oil used to seal the rotating shaft in mechanical equipment, and the cavity is basically stationary, so the oil seal is also called a rotating shaft lip seal. For the oil seal with auxiliary lip, the auxiliary lip acts as a dustproof to prevent the intrusion of impurities to extend the life of the oil seal, but the auxiliary lip is often poorly lubricated and the friction force is large, which causes the dry seal of the oil seal to be damaged by damage. Be sure to fill grease between lips.

3. Problems with gaps

In the assembly process, if the size of the spacer is not proofread carefully and the assembly test is carried out, the temperature will rise rapidly after a certain time. The size of the outer ring of the bearing is determined by the end cover and the seat of the bearing seat, the size of the spacer is reduced, the size of the inner ring will be adjusted by the round nut, and finally compressed, the axial clearance of the bearing becomes smaller, which causes heat during operation.

④ Four, lubrication problems

The amount of grease in the bearing should not be too much. If the amount of grease is too large, the friction torque will increase and the temperature of the bearing will increase. If the amount of grease is too small, reliable lubrication will not be obtained and dry friction will occur. Generally speaking, the appropriate amount of grease is 1/3 to 1/2 of the total void volume in the bearing. Therefore, according to the requirements of use, the appropriate amount of grease should be regularly injected.

In summary, Longjian Group recommends the PCZ heavy hammer crusher to replace the old jaw crusher and plate hammer crusher for you. Welcome to visit the site, please pay attention to the official website of Longjian Group m.luodong.net.

-

Focus Project | With a total investment of 487 million yuan, The customer of Sanming Heavy Industry in Liuzhou, Guangxi will soon build an annual output of 4 million tons of fine sand aggregate production line

Focus Project | With a total investment of 487 million yuan, The customer of Sanming Heavy Industry in Liuzhou, Guangxi will soon build an annual output of 4 million tons of fine sand aggregate production line -

The 2022 Spring Festival holiday notice of Longjian Group

The 2022 Spring Festival holiday notice of Longjian Group -

Longjian Group held a virtual equity incentive promotion meeting in the fourth quarter of 2021

Longjian Group held a virtual equity incentive promotion meeting in the fourth quarter of 2021 -

Hand in hand to build heart to heart | Longjian Group Party branch went to Dashu Village to carry out "Urban and rural branches hand in hand" pair to build donation activities

Hand in hand to build heart to heart | Longjian Group Party branch went to Dashu Village to carry out "Urban and rural branches hand in hand" pair to build donation activities -

.png) Chongqing "Meter" high-speed Railway Network Construction | Full Construction in five years, Full operation in ten years -- Chengdu-Chongqing Middle Line high-speed railway Construction "Acceleration"

Chongqing "Meter" high-speed Railway Network Construction | Full Construction in five years, Full operation in ten years -- Chengdu-Chongqing Middle Line high-speed railway Construction "Acceleration" -

How to create green mines and green factories?

-

In the process of installation and acceptance of equipment of sand and gravel aggregate production line with production capacity of 600 tons at the beginning of construction in Hubei Province

In the process of installation and acceptance of equipment of sand and gravel aggregate production line with production capacity of 600 tons at the beginning of construction in Hubei Province -

Warmly congratulated: Mr. Long Fujian, chairman of the group company, was elected vice president of Chongqing sand and stone association

Warmly congratulated: Mr. Long Fujian, chairman of the group company, was elected vice president of Chongqing sand and stone association